NEWS

NEWS

19

2025

-

03

Shikefeng made its debut on the global agrochemical stage in CAC2025, and its genuine fertilizers have been highly favored both at home and abroad!

The 25th China International Agrochemicals and Plant Protection Exhibition

The 25th China International Agrochemicals and Plant Protection Exhibition (CAC 2025) was held at the National Exhibition and Convention Center (Shanghai) from March 17th to 19th, 2025. Shikefeng Chemical once again took the stage at CAC with its full range of products covering soil improvement, crop nutrition and ecological agriculture. It not only showcased the latest achievements of Shikefeng in the entire agricultural industry chain to the world, but also highlighted the leading position of China's agricultural science and technology development globally.

In this exhibition, Shi Kefeng Chemical exhibited more than 40 kinds of high-quality products, including compound fertilizer, water-soluble fertilizer, tower fertilizer, monoammonium phosphate, ammonium phosphate, etc. Among them, the new products acid-base balanced fertilizer, silicon calcium potassium magnesium zinc fertilizer, biological organic fertilizer and other efficient microbial fertilizer series also appeared in the exhibition.

Shi Kefeng - Exhibition

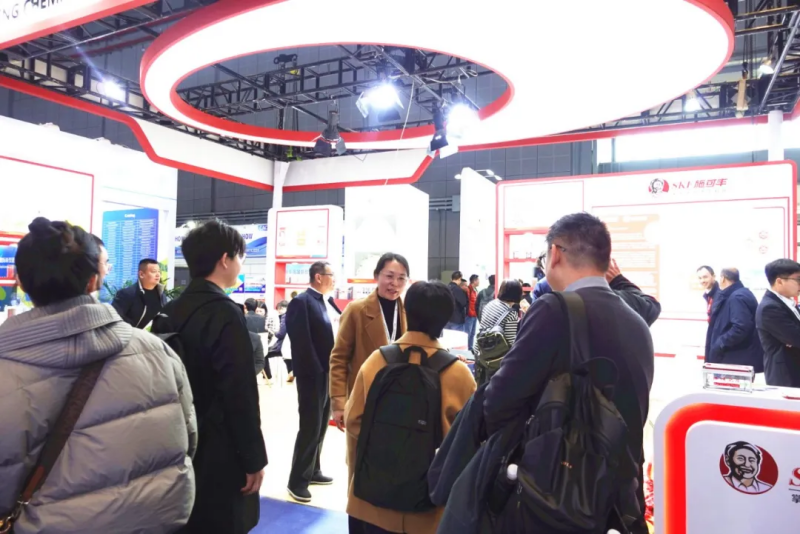

The scene was extremely popular

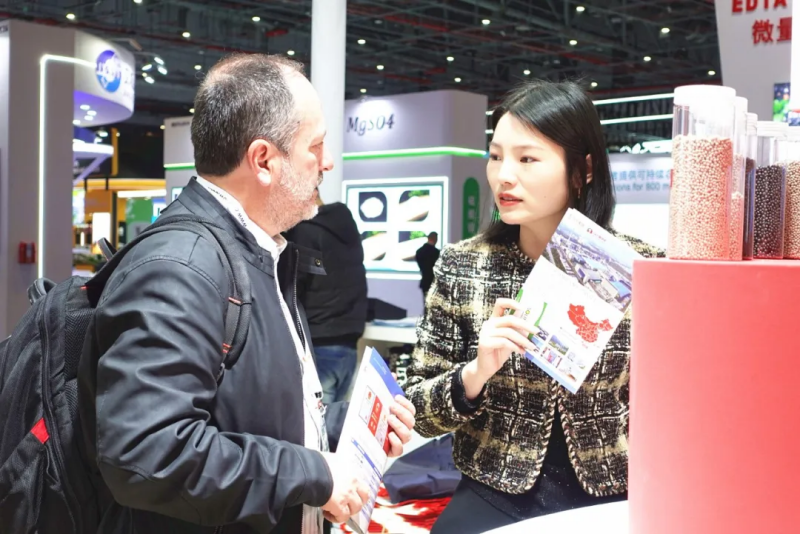

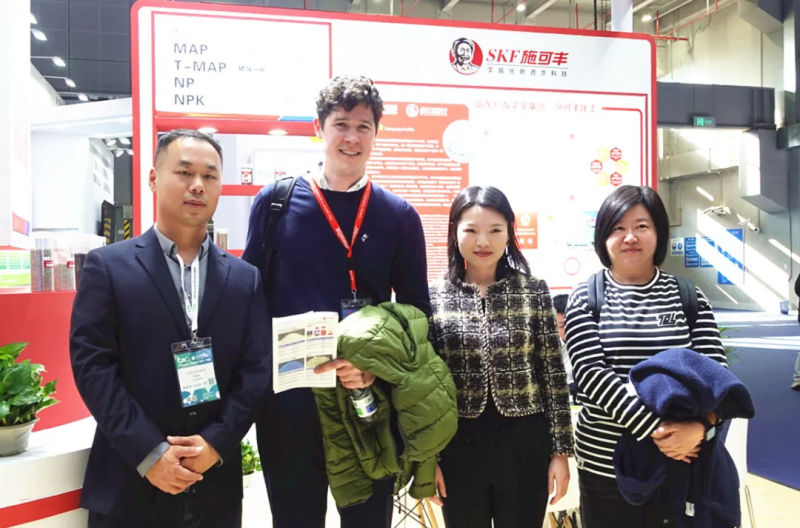

At the booth of Shikefeng, visitors came one after another and the scene was packed with people. The consultation heat continued to rise. Sun Feifei, the vice president of the group, led the company's foreign trade team to warmly receive every visitor. Through professional explanations, product displays, and technical Q&A, they precisely matched the customer's needs, laying a solid foundation for subsequent cooperation.

Shikefeng - The internationalization process has reached a new level

Xianglong International Trade Department is committed to developing import and export business, focusing on global agricultural demands, and providing one-stop services covering product marketing, full value chain construction, and soil problem-solving, fully expanding its overseas territory. The products sell well in dozens of countries and regions around the world, including Brazil, Peru, South Africa, Japan, Thailand, Turkey, Pakistan, etc. At this exhibition, Shikefeng, with its technical features of "green efficiency and precise regulation", attracted global purchasers to consult and negotiate. The cooperation intentions have been continuously heating up, and Shikefeng's internationalization process has reached a new level!

As the annual grand event of the global agrochemical industry, the CAC Exhibition has become a global business exchange platform that links the upstream and downstream and connects the domestic and international markets. The grand opening of CAC2025 will further leverage the role of the CAC exhibition in connecting the world, serving the industry, and empowering enterprises, leaving a remarkable mark on the path of serving global agriculture.

Shikefeng will leverage the international platform of the CAC exhibition, through product technological innovation and global layout, to continue to be committed to promoting the modernization process of agriculture, jointly explore the cutting-edge technologies in the agrochemical industry, and work together to create a new future for green agriculture!

Contributed by MAO Yuqing and Ji Guangling

Typesetting: Ji Guangling

Reviewer: Liu Chuanying

Relevant News